YJ-SR Base Oil Re-refining Plant

YJ-SR Base Oil Re-refining Plant

Liquid-Liquid centrifugal extractor can separate two different immiscible liquids, it has been used widely in industries such as the oil extraction, pharmaceutical, fine chemical, food products, Environmental protection industry and wastewater treatment, etc. Our company can design and adjust centrifugal speed or inlet quantity of the centrifugal extractor according to the density of the different liquid mediums.

Working principle of centrifugal extractor:

- Liquid-Liquid Centrifugal Extractor uses the rotation of the rotor inside a centrifuge to mix two immiscible liquids outside the rotor and to separate the liquids in the field of gravity inside the rotor.

- Separation: Direct feed minimizes the shear forces of the mixed liquid stream, thereby increasing the efficiency of the separation. The mixed liquid enters the extractor directly from the bottom inlet of the rotary drum, is centrifugally separated by the rotating drum, and enters the separation zone, and the separation is continuously performed.

- Extraction: Two-phase liquid enters the extractor from the inlets of both side of the extractor and mixes in the annular gap between the drum and the shell, usually it reach equilibrium in a matter of seconds. The special structure inside the annulus optimizes the mass transfer effect. The separation is continuously performed inside the drum.

- In-situ cleaning: can realize the liquid/liquid centrifugal extractor disassembly-free cleaning function.

- Multi-step operation: Each centrifugal extractor represents a theoretical stage. A separation system is composed of a series of centrifugal extractors, which can realize multi-step countercurrent or transverse flow extraction.

Design features of liquid centrifugal extractor:

- Compact structure: Direct motor drive, no transmission accessories, compact structure, save operation space.

- Strong adaptability: Compared with traditional van and tower extraction equipment, the stage has a short retention time, rapid phase separation, and a wide range of flow ratios. It can meet liquids separation with different density and viscosity by changing the raft and frequency.

- High extraction efficiency: The phase equilibrium is established quickly, and it is easy to realize single-stage or multi-stage series countercurrent or cross-flow washing and extraction.

- Fully automatic operation: Continuous and uninterrupted operation, and can also be used in small batches and varieties liquid-liquid extraction.

- Low investment costs: The internal volume is small. The consumption of extractant, solvent or detergent are minima.

- Good sealing performance: Meet the application environment and GMP regulations for explosion-proof and toxic, harmful and volatile media.

- Optional configuration: According to different needs, you can choose an anti-emulsification device, in-situ cleaning mechanism, or Frequency converter, etc.

Application Field:

- Centrifugal extractor, also as know as Liquid-liquid centrifugal extractors or centrifugal contactor, which has been used widely in industries such as the pharmaceutical, fine chemical, food products, nuclear, etc.

- Oil industry: lubricating oil extraction, diesel desulfurization and so on.

- Pharmaceutical industry: such as used for extracting ethyl acetate, methylene dichloride, normal butanol, chloroform, or extracting the Chinese traditional medicine.

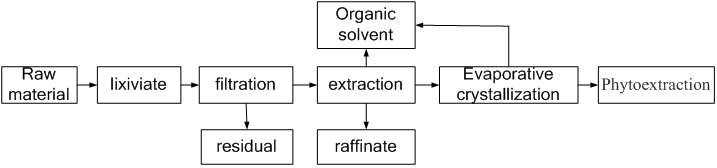

- Food industry: extraction and separation of lactic acid and citric acid fermentation broth, edible oil, food pigment, etc.

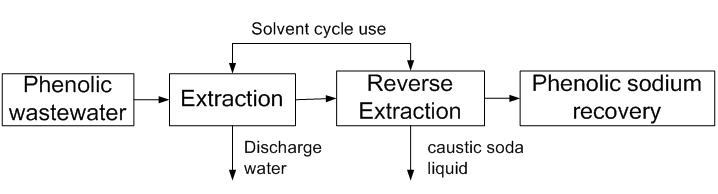

- Environmental protection industry: used single-stage or multistage extraction and reverse extraction to treat wastewater with phenol or acid, printing and dyeing wastewater (H acid, T acid, etc.), DMF wastewater, naphthalene sulfonic acid wastewater, etc.

- Oil-water separation or extraction for marine sewage, groundwater, or separate organic solvent from the water.

Extraction technology of liquid centrifugal extractor:

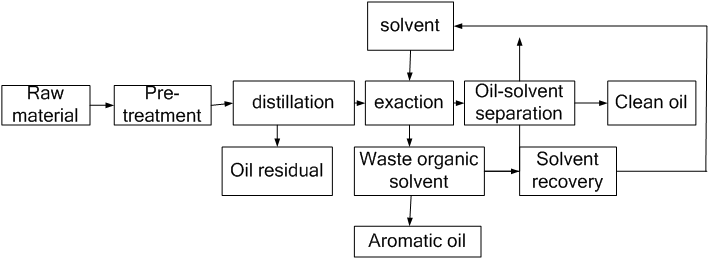

- Oil extraction:

- Environmental protection (treat wastewater with phenol):

- Phytoextraction:

Research and development strength:

The Research and development team used a combination of traditional methods and computational fluid dynamics simulation methods to design the hydraulic design of a cylindrical centrifugal extractor. The performance prediction results were obtained by analyzing the internal flow field of the cylindrical centrifugal extractor. Intensity analysis of key components was performed using finite element technology. The vibration performance of the centrifugal extractor was evaluated using a kinetic model and an acceleration acquisition experiment. Endurance test and hydraulic performance tests were carried out. The reliability of the cylindrical centrifugal extractor operating under design conditions was verified by data recording and analysis, as well as the overall inspection after the test.

YANGJIANG is committed to new product research and development, dedicated to providing you with the highest cost-effective, high-quality products and meticulous after-sales service. If you have any requirements and questions about Single-stage and Multi-stage Centrifugal Extractor, please feel free to contact us.