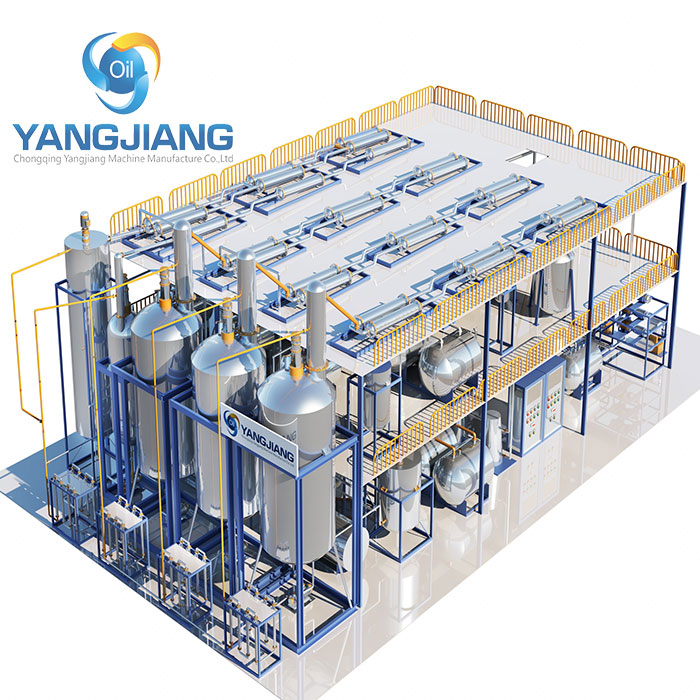

YJ-TY Used Engine Oil to Base Oil Recyling Plant

YJ-TY Used Engine Oil to Base Oil Recyling Plant

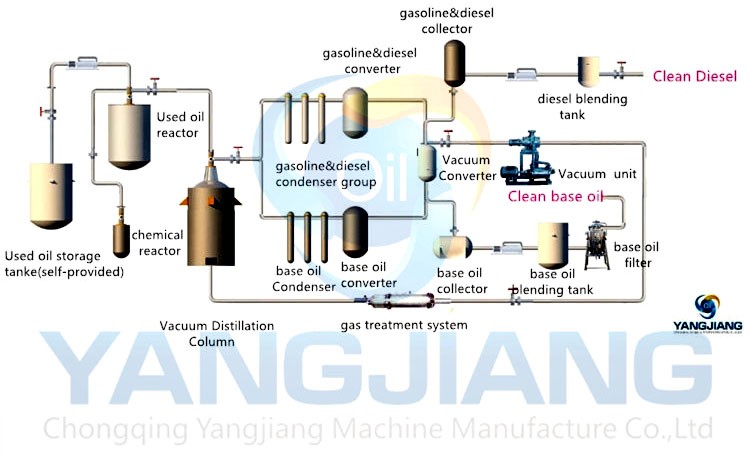

Yangjiang Company uses vacuum distillation technology to recycle the waste oil into base oil. In general, water and dissolved low boiling point organic removed by atmospheric or moderate vacuum distillation. Lube oil is then recovered and fractionated by distillation. Light ends by-products are commonly used for plant combustion fuels. Diesel and gasoline can be recovered as high-quality by-products after further advanced treatment. Residual streams from distillation can be used by the asphalt industry as an asphalt flux to produce roofing asphalt, paving asphalt, insulating materials, and other asphalt-based products.

Used Engine Oils To Base Oil Refinery Equipment is particularly suitable for regenerating used engine oil including diesel engine oil, gasoline engine oil, motor oil, ship engine oil, truck oil, and used hydraulic oil, other used machinery lubrication oil into SN150, SN300, SN 500 base oil.

Description

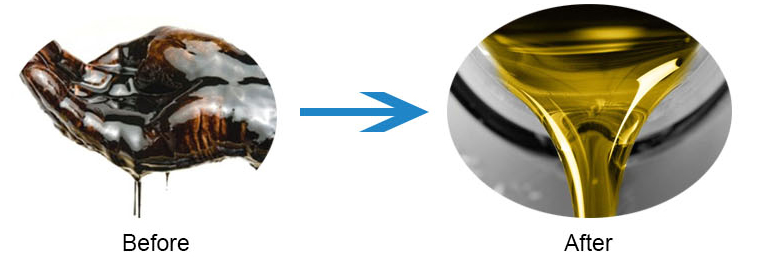

Producing Base Oil by Used Engine Oil Refining Machine is particularly suitable to regenerate used engine oil including diesel engine oil, gasoline engine oil,motor oil,ship engine oil, truck oil, and used hydraulicoil, other used machinery lubrication oil Producing Base Oil by Used Engine Oil Refining Machine can remove water, impurity, acid base, and tiny impurity dispersed in oil such as carbon particles, heavy metal ions, deep oxides, as well as bad substance such as colloid and bitumen. Thus, the clarity of oil is recovered, engine oil quality improved, performance of engine restored, abrasion reduced, these would ensure correct operation of lubricant system of a engine and extend the life time of engine oil and engine as well.

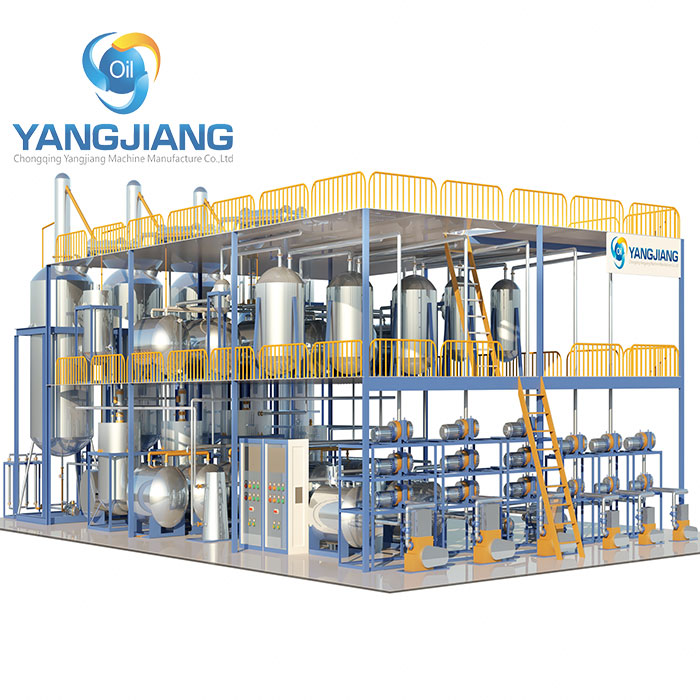

What kinds of technology we use?

We use vacuum distillation to remove the contaminants in the used oil, it will reduce the pollution and recycle the oil for reuse. Vacuum distillation is a method of distillation that the pressure above the liquid mixture to be distilled is reduced to less than its vapor pressure (usually less than atmospheric pressure), causing evaporation of the most volatile liquids (those with the lowest boiling points).

The whole process is physical distillation, no acid and no chemical will be contained in clean oil. And the machine will distill out what the used oil contains, it won’t change the oil quality and components.

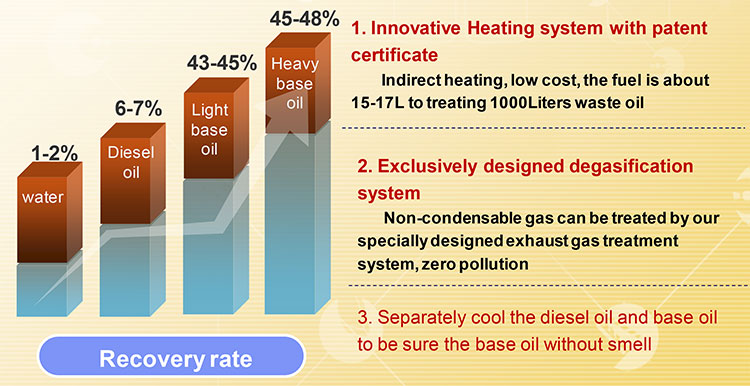

The base oil recovery rate is 82-90% according to the raw material quality, color index 1-1.5.

Product Parameters

| Item | Test standard | Data | |

| Light base oil | Heavy base oil | ||

| Viscosity(40℃) | mm2/s | 16~32 | 28~72 |

| Viscosity index | N/A | ≥99 | >110 |

| Appearance | N/A | Transparency | Transparency |

| Color index | ASTMD1500 number | ≤1 | ≤2 |

| Pour point | ℃ | -15℃ | -10℃ |

| Water content | %(w/w) | ≤0.05 | ≤0.05 |

| flash point(open) | ℃ | ≥180 | ≥210 |

| ash content | %(w/w) | 0.005 | 0.005 |

| carbon residue | %(w/w) | ≤0.13 | ≤0.13 |

| Corrosion(copper/100℃/3H) | N/A | Qualified | Qualified |

| Acidity | Mg KOH/g | ≤0.05 | ≤0.05 |

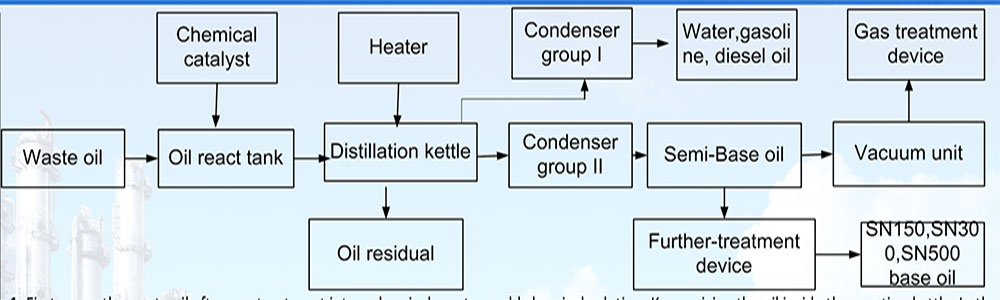

Flow Chart of Used Engine Oils To Base Oil Refinery Equipment:

Working Process:

1. First pump the waste oil after pre-treatment into a chemical reactor , add chemical solution. Keep mixing the oil inside the reaction kettle. In the reaction kettle make the oil static after a mixing, we have the impurities and part of the colloid at the bottom of reaction kettle separated. After this chemical catalyst treatment of oil, the oil will not be cracked even it is heated up to 400 degrees in atmosphere. (in the atmosphere, without the treatment ,the oil starts to be cracked at 300 degree, it obviously declines the quality of recycled oil and recovery rate).

2. After chemical treatment, the waste oil is heated by electric heater, to control the oil temperature within 330 degrees. As the temperature of the waste oil rises to around 55℃ ,first cut of gasoline start to release form the waste oil. As the temperature of the oil rises to around 110°C – 220°°C, the second cut of diesel oil are released. Base Oil is the main product and its distillation starts at around 220°C and continues up to 330°C. Light base oil are distilled out around 220°C-300°C,and heavy base oil distills out during 300°C -330°C. Finally, the process ends when the residual material in the waste oil does not vaporize. At this point, the heating in the distillation process is stopped and the process is essentially complete. We can pump oil residual out to use as bitumen and heavy fuel oil.

3. Yangjiang’s machine was contain heating system, the fuel is diesel oil, fuel consumption is about 13-18Liters diesel oil for recycling 1000Liters waste oil.

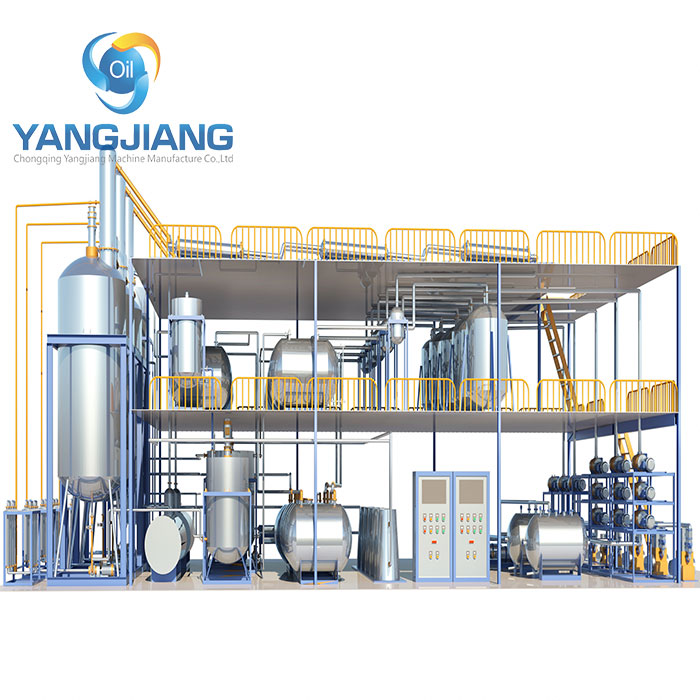

YJ-TY series is suitable for gasoline motor oil, diesel motor oil, all kinds of engine oil, mineral oil, synthetic oil, transmission oil, hydraulic oil and other used lubricant oil to clean base oil (SN150, SN300, SN350, SN500).

Features

All our machine are designed with times and year experiments, we also have cooperation refinery in China.

- This machine is suitable for all kinds of waste industrial oil form everywhere

- High quality recycled base oil; lube oil can be reused directly.

- The recovery rate is more than 85%.

- Eco-friendly and no bad smell, all gas can be draw to heating burner.

- Low chemical cost, only 30usd for recycling one ton used oil; low labor cost, only one person can operate.

About Us

YANGJIANG provide all used lube oil recycling equipment and technology. This is more than simply used lubrication oil disposal,we are not just purify used oil,instead, we developed an amazing regeneration process than can reclaim all kinds of waste black lube oil to clean base oil.This is the most effective process for lube oil recycling , TY vacuum system is to refine waste oil in a batch process.Waste lube oil after pre-treatment ,will be pumped into a catalyst reactor we will add two kinds catalyst blend with oil and heat in a distillation kettle under vacuum