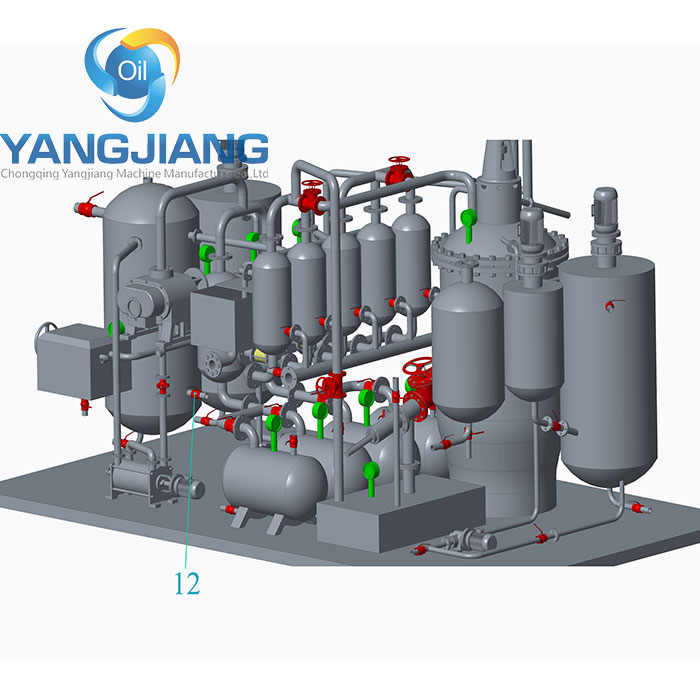

YJ-TY Lube Oil Recycling Plant

YJ-TY Lube Oil Recycling Plant

Used oil still has lubricating value and heat value, used oil can be re-refined into base lube oil or recycled as fuel oil, or used as feedstock to produce petroleum-based products or other commercially valuable products via different processes. Yangjiang’s pyrolysis oil distillation plant adopts vacuum distillation technology to recycle all kinds of lube oil into a light yellow base oil, like SN100, SN150, SN300, etc.

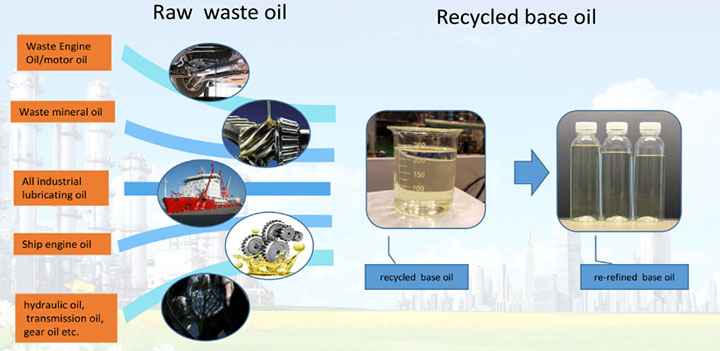

The Lube Oil Recycling Plant can recycle all kinds of lube oil, engine oil, motor oil, ship oil, transformer oil, hydraulic oil, gear oil to clean base oil, the recovery rate is more than 85%, recycled base oil flash point is 190-220degree, also this oil recycling machine can change black oil to yellow, remove bad odor.

Description

This machine can recycle gasoline motor oil, diesel motor oil, all kinds of engine oil, mineral oil, synthetic oil,and other waste lube oil to clean base oil, like SN150, SN300, SN350, SN500. Cars, trucks, farm machines and ships all need regular lubricating oil changes. Motor oil picks up a variety of hazardous contaminants when used in engines and transmissions. These contaminants include lead, cadmium, chromium, arsenic, dioxins, benzene and polycyclic aromatics. If used motor oil and the contaminants it contains are disposed of inappropriately and released into the environment, will have the potential to pollute land, water and infrastructure, so we need to recover and recycle as much of it as possible. Our company made great efforts to find new technology in vacuum distillation plant, which can distill all kinds of waste oil into available oil with a high recovery rate.

Technical specification of lube oil recycling plant

| Recycled Oil Parameter | |||

| Item | Unit | Light Base Oil | Medium/Heavy Base Oil |

| Viscosity(40℃) | mm2/s | 16~32 | 28~72 |

| Viscosity Index | ≥99 | >110 | |

| Pour Point | ℃ | -15 | -10 |

| Color Index | ≤1 | ≤1.5 | |

| Water Content | %(W/W) | ≤0.05 | ≤0.05 |

| Flash Point(open) | ℃ | ≥190 | ≥225 |

| Ash Content | %(W/W) | 0.005 | 0.005 |

| Carbon Residue | %(W/W) | ≤0.13 | ≤0.13 |

| Corrosion | copper, 100℃, 3h | Qualified | Qualified |

| Acidity | mg/KOH/g | ≤0.05 | ≤0.05 |

Base oil form petroleum

- Modern lubricants are mostly formulated form a wide range of base fluids and different packages of chemical additives. The majority of the base fluids are produced for the recycling of crude oil since large crude oil refining operations can produce base oil with high quality and excellent performance at an economical price. base oil composition may vary depending on the crude oil it is made form. For different applications, lubricants are formulated by blending different base oils and additives to meet a series of performance specifications. Hence, formulations and performance specifications for automotive lubricants, industrial lubricants, aviation lubricants, and marine lubricants are greatly different.

- In a modern oil recycling plant, base oil plants(lube plants)are integrated with the mainstream refinery process. Overall production capacity for the lubricant base oil is only a very small part(about 1percent) of the total recycling production lines.

- The feedstock for this process is residue from atmospheric distillation, also named vacuum distillation.

- Vacuum distillation is a method of distillation whereby the pressure above the liquid mixture to be distilled is reduced to less than its vapor pressure (usually less than atmospheric pressure), causing evaporation of the most volatile liquid(s) (those with the lowest boiling points).

- This distillation method works on the principle that boiling occurs when the vapor pressure of a liquid exceeds the ambient pressure. Vacuum distillation is used with or without heating the mixture. this is the most effective process for used oil recycling, waste lube oil after pre-treatment, will be pumped into a distillation kettle under vacuum. As the temperature in the kettle rises, various cuts are liberated and rise as vapors, to be condensed in a condenser. The condenser, along with the heating kettle, is maintained under vacuum by the vacuum pumping system. The condensed products are available as different products corresponding to various kettle temperatures.

The Harm of containing water, gas and impurities in the oil:

- The oil will oxidate rapidly and product acidic material, eroding the metal surface;

- The chemical additive invalidates, reducing the thickness of lubrication film and aggravating the machine abrasion.

- The lubrication, cooling, the flow were reduced then accelerating the fatigue of the metal surface;

- The ice crystals which formed under low temperature will block elements and lower the systemic rigidity

- The slow response of the system run with irregular movement,lower the conduction performance

- The high temperature of the oil can’t cool effectively.

- The oil pump and the power equipment were damaged because of the cavitations.

- If we deal with this waste engine oil by burning or burying, it does not only bring serious environmental pollution, also caused a huge waste of energy. So on the basis of reusing resources or environmental protection, or view the point of being able to bring enormous economic benefits for the producers, the waste oil for recycling has a very good prospect. You can choose our distillation machine to recycle waste oil into base oil or diesel oil.

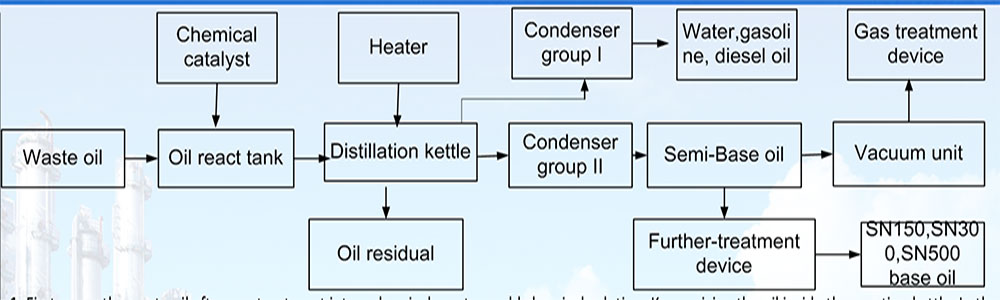

Flow Chart of YJ-TY Lube Oil Recycling Plant:

Working Process

1. First pump the waste oil after pre-treatment into a chemical reactor , add chemical solution. Keep mixing the oil inside the reaction kettle. In the reaction kettle make the oil static after a mixing, we have the impurities and part of the colloid at the bottom of reaction kettle separated. After this chemical catalyst treatment of oil, the oil will not be cracked even it is heated up to 400 degrees in atmosphere. (in the atmosphere, without the treatment ,the oil starts to be cracked at 300 degree, it obviously declines the quality of recycled oil and recovery rate).

2. After chemical treatment, the waste oil is heated by electric heater, to control the oil temperature within 330 degrees. As the temperature of the waste oil rises to around 55℃ ,first cut of gasoline start to release form the waste oil. As the temperature of the oil rises to around 110°C – 220°°C, the second cut of diesel oil are released. Base Oil is the main product and its distillation starts at around 220°C and continues up to 330°C. Light base oil are distilled out around 220°C-300°C,and heavy base oil distills out during 300°C -330°C. Finally, the process ends when the residual material in the waste oil does not vaporize. At this point, the heating in the distillation process is stopped and the process is essentially complete. We can pump oil residual out to use as bitumen and heavy fuel oil.

3. Yangjiang’s machine was contain heating system, you can choose hot gas heating system, Electromanetic heating system or Tubular Heating system.

The fuel is diesel oil, fuel consumption is about 15-20Liters diesel oil for recycling 1000Liters waste oil.

What kinds of waste oil can be recycled by the YJ-TY Lube Oil Recycling Plant?

- Waste Engine Oil

- Black motor oil

- Waste mineral oil

- Used industrial lubricating oil

- Ship engine oil

- Hydraulic oil, transmission oil, gear oil and all industrial lube oil, etc.

Features of lube oil recycling plant:

- This machine is suitable for all kinds of waste industrial oil form everywhere

- High quality recycled base oil; lube oil can be reused directly.

- The recovery rate is more than 85%.

- Eco-friendly and with no bad smell, all gas can be a draw to the heating burner.

- Low chemical cost, only 30usd for recycling one ton used oil; low labor cost, only one person can operate.

- All our machines are designed with time and year experiments, we also have cooperation refinery in China.

The function of the YJ-TY Lube Oil Recycling Plant

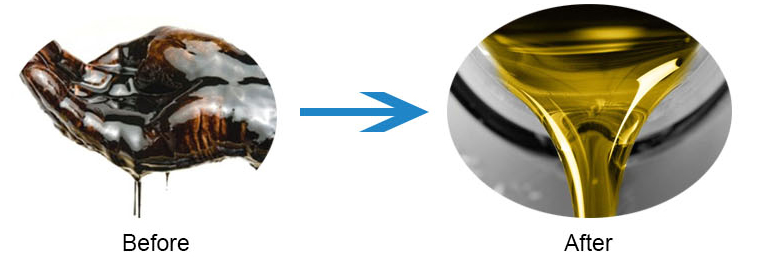

This machine can recycle the waste oil to yellow base oil. It not only removes the impurities, water, and acid matter, organic and inorganic acid effectively, but also can remove carbon particulate matter and peroxides. In gas/diesel engine oil, bitumen and colloid and other sludge can be removed similarly, and it can change the color to golden color, remove bad odor.

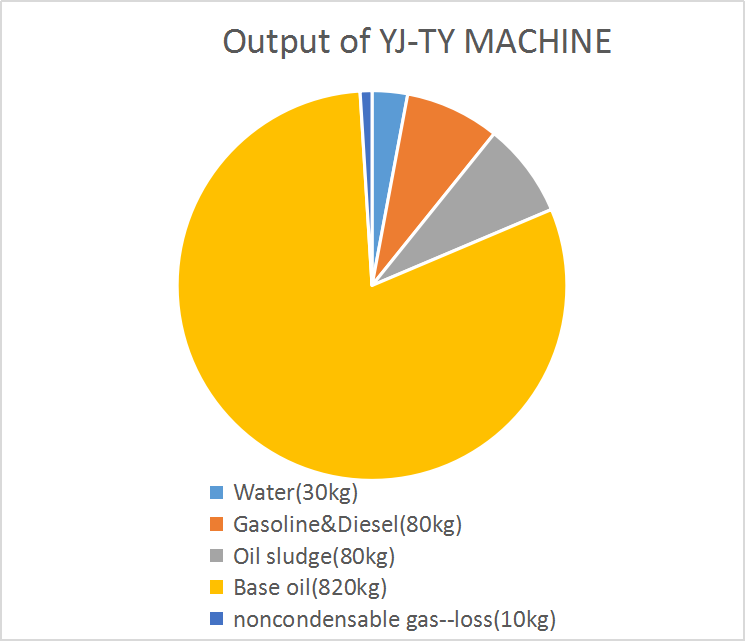

Material Balance (Below table is for your reference, the real condition should be based on your raw material condition)

| Input | |

| Item | Quantity |

| waste engine oil | 1000kg |

| catalyst | 20kg |

| Total input | 1020kg |

| Out put | |

| Item | Quantity |

| water | 30kg |

| Gasoline&Diesel | 80kg |

| oil sludge | 80kg |

| Base oil | 820kg |

| noncondensable gas(loss) | 10kg |

| Total output | 1020kg |

YANGJIANG Machine Manufacture Co., Ltd has unique technology and rich experience in the waste oil recycling industry, the company constantly seeks development, extensively absorbs the world’s advanced oil purification technology, and is committed to research and development in the field of oil treatment. If you have any requirements or questions about Engine Oil Recycling Machine, please feel free to contact us.