YJ-TY Base Oil Distillation Machine

YJ-TY Base Oil Distillation Machine

Waste Oil Distillation Plant to recycle waste oil into a base oil. Vacuum distillation is a method of distillation that the pressure above the liquid mixture to be distilled is reduced to less than its vapor pressure (usually less than atmospheric pressure), causing evaporation of the most volatile liquids (those with the lowest boiling points). As with distillation, this technique separates compounds based on differences in boiling points. In general, water and dissolved low boiling point organic removed by atmospheric or moderate vacuum distillation. Lube oil is then recovered and fractionated by distillation. Light ends by-products are commonly used for plant combustion fuels. Diesel and gasoline can be recovered as high-quality by-products after further advanced treatment. Residual streams from distillation can be used by the asphalt industry as an asphalt flux to produce roofing asphalt, paving asphalt, insulating materials, and other asphalt-based products.

Description

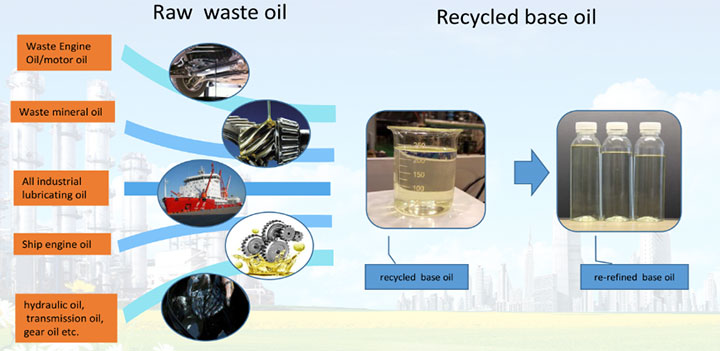

YANGJIANG Machine Manufacture Co., Ltd is engaged in researching, developing, and manufacturing waste engine recycling and refining equipment. Our oil recycling equipment has a wide range of applications for all kinds of waste industrial oil. Our used oil distillation plant can recycle waste oil to base oil or diesel oil, and now we have new technology solvent extraction technology, which can refine the oil to white-water color and reduce sulfur to 50-100ppm.

Our machine was installed in many places in China market and has been exported to different countries, like Greece, Algeria, Liberia, Saudi Arabia, UAE, Singapore, Malaysia, Indonesia, Hongkong, Egypt, Kenya, Senegal, Panama, etc.

YANGJIANG is committed to new product research and development and is dedicated to providing you with the highest cost-effective, high-quality products and meticulous after-sales service!

Technical Parameter of Used Oil Distillation Plant

| YJ-TY | ||||||

| Specifications | Unit | 1 | 5 | 10 | 20 | 30 |

| Handling capacity | L/d | 1000L | 5000L | 10,000L | 20,000L | 30,000L |

| Base oil Recovery | % | 80-85% | ||||

| Working pressure | pa | ≤60 | ||||

| The Highest vacuum Degree | Mpa | -0.1MPA- -0.092 | ||||

| Temperature Range | ℃ | ≤330-350 | ||||

| Machine Dimension | M | 5.3*2.3*5 | 16*6*6 | 25*6*8 | 30*8.5*8 | 30*10*10 |

| Total power | kw | 31 | 43 | 55 | 95 | 125 |

| Power Supply | V | 380V or Agreement | ||||

| Equipment weight | T | 6.5 | 11.6 | 14.8 | 21.5 | 29 |

| Cooling water | M3 | 40 | 60 | 80 | 120 | 150 |

| Operating area | M2 | 80 | 180 | 360 | 500 | 800 |

| Container | 1*20’ | 2*40’ | 3*40’ | 3*40’+1*20’ | 4*40’ | |

| Lead time | day | 30 | 60 | 75 | 80 | 90 |

| Note:1) Our machine has multiple handling capacity choice:1-100tons per day.2) The heating method can be fuel oil, natural gas, electricity, coal and wood, etc.3) Fuel consumption: 15-17Liters diesel oil to recycle 1000Liters waste oil. | ||||||

What technology do we use?

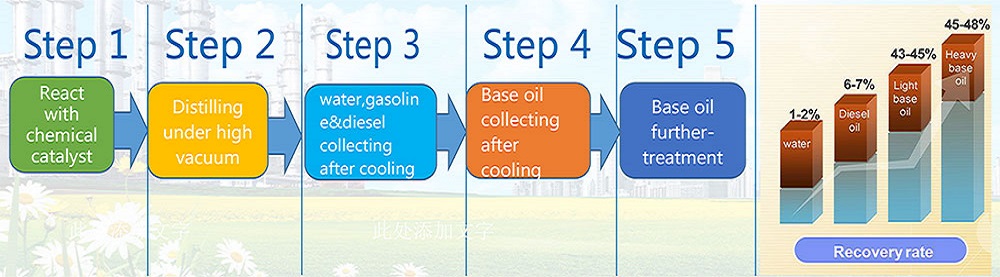

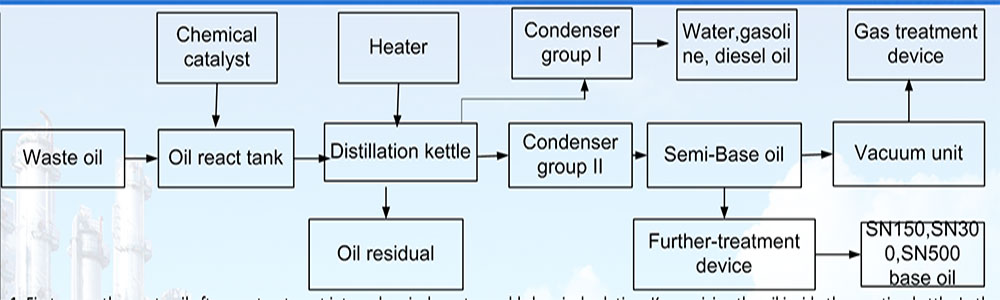

Yangjiang Company uses vacuum distillation technology to recycle waste oil into a base oil. Vacuum distillation is a method of distillation that the pressure above the liquid mixture to be distilled is reduced to less than its vapor pressure (usually less than atmospheric pressure), causing evaporation of the most volatile liquids (those with the lowest boiling points). As with distillation, this technique separates compounds based on differences in boiling points. In general, water and dissolved low boiling point organic removed by atmospheric or moderate vacuum distillation. Lube oil is then recovered and fractionated by distillation. Light ends by-products are commonly used for plant combustion fuels. Diesel and gasoline can be recovered as high-quality by-products after further advanced treatment. Residual streams form distillation can be used by the asphalt industry as an asphalt flux to produce roofing asphalt, paving asphalt, insulating materials, and other asphalt-based products.

- First, pump the waste oil after pre-treatment into a chemical reactor, add the chemical solution. Keep mixing the oil inside the reaction kettle. In the reaction kettle make the oil static after mixing, we have the impurities and part of the colloid at the bottom of the reaction kettle separated. After this chemical catalyst treatment of oil, the oil will not be cracked even it is heated up to 400 degrees in the atmosphere. (in the atmosphere, without the treatment, the oil starts to be cracked at 300 degrees, it obviously declines the quality of recycled oil and recovery rate).

- After chemical treatment, the waste oil is heated by an electric heater, to control the oil temperature within 330 degrees. As the temperature of the waste oil rises to around 55℃, the first cut off gasoline starts to release from the waste oil. As the temperature of the oil rises to around 110°C – 220°°C, the second cut of diesel oil is released. Base Oil is the main product and its distillation starts at around 220°C and continues up to 330°C. The light base oil is distilled out around 220°C-300°C, and heavy base oil distills out during 300°C -330°C. Finally, the process ends when the residual material in the waste oil does not vaporize. At this point, the heating in the distillation process is stopped and the process is essentially complete. We can pump oil residual out to use as bitumen and heavy fuel oil.

- Yangjiang’s machine was contain a heating system, the fuel is diesel oil, fuel consumption is about 13-18Liters diesel oil for recycling 1000Liters waste oil.

Recycled base oil parameter

| No. | Item | Unit | Technical data | |

| Light base oil | Medium/heavy base oil | |||

| 1 | Viscosity(40℃) | mm2/s | 16~32 | 28~72 |

| 2 | Viscosity index | ≥99 | >110 | |

| 3 | Appearance | Transparency | Transparency | |

| 4 | Color index | ASTMD 1500 Number | ≤1 | ≤2 |

| 5 | Pour point | ℃ | -15 | -10 |

| 6 | Water content | %(W/W) | ≤0.05 | ≤0.05 |

| 7 | Flash point(open) | ℃ | ≥190 | ≥225 |

| 8 | Ash content | %(W/W) | 0.005 | 0.005 |

| 9 | Carbon residue | %(W/W) | ≤0.13 | ≤0.13 |

| 10 | Corrosion(copper,100℃,3h) | Qualified | Qualified | |

| 11 | Acidity | mgKOH/g | ≤0.05 | ≤0.05 |

| 12 | Demulsibility(54C) | GB/T7305-2003 (2004) | 5min | 5min |

| 13 | Oxidation Resistance | SH/T0193-2008 | 350MIN | 350MIN |

| 14 | Density | Kg/m3 | 837 | 850 |

Features of used oil distillation plant

- Vacuum distillation is a method of distillation that the pressure above the liquid mixture to be distilled is reduced to less than its vapor pressure (usually less than atmospheric pressure), causing evaporation of the most volatile liquids (those with the lowest boiling points).

- This is the most effective process for used oil recycling; the YJ-TY vacuum system is to refine waste oil in a batch process. Waste lube oil after pre-treatment will be pumped into a distillation kettle under a vacuum. As the temperature in the kettle rises, various cuts are liberated and rise as vapors, to be condensed in a condenser. The condenser, along with the heating kettle, is maintained under vacuum by a vacuum pumping system. Different products will be distilled out and condensed while the kettle is not responding to temperatures.

- The whole process is physical distillation, no acid and no chemical will be contained in clean oil.

- The machine will distill out what the used oil contains, it won‘t change the oil quality and components, color index 1-1.5.

Advantages of Yangjiang YJ-TY Used Oil Distillation Plant

- The recycling rate is more than 87%; a machine can recycle all kinds of waste industrial oils from everywhere;

- Two kinds of heating system you can choose: superior heating system+ special designed distillation system definitely will get you best oil in the peers, high efficiency and good quality equipment can save energy and money in the long run;

- Self-developed chemicals: delays the waste oil cracking into diesel under high temperature, and reduces the coking, greatly raise the recycling rate;

- Exhaust gas treatment equipped: no matter how strict the emission standard is, our machine will meet your need;

- Cool system: We cool the diesel oil and base oil separately be sure the base oil without diesel smell. Most of our competitors cool the diesel oil and base oil in the same condenser, so their base oil has a smell.

With our machine, you can get a high recycling rate for base oil.

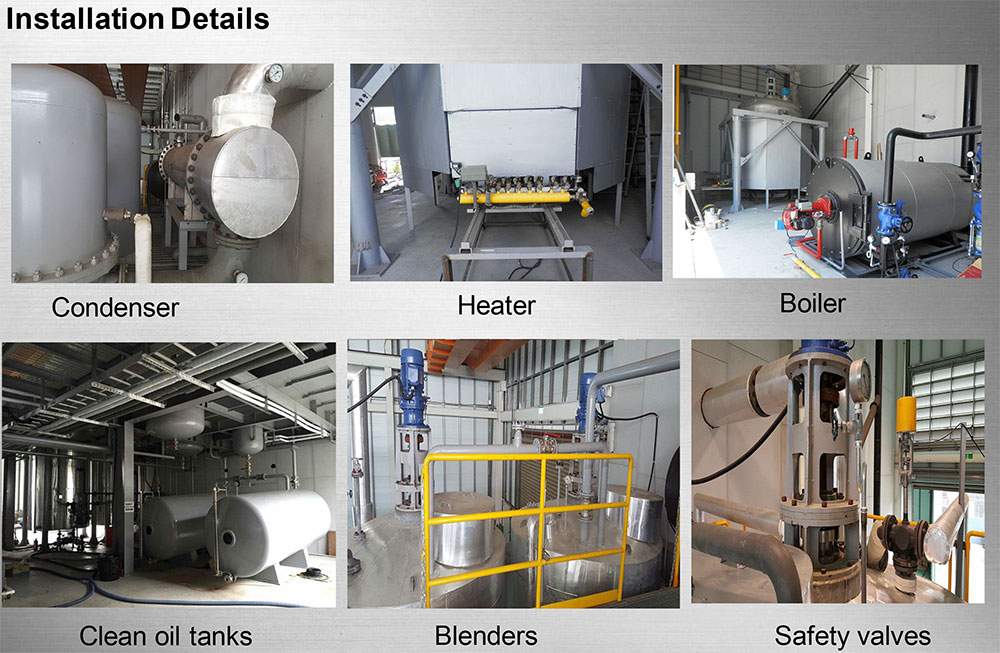

Installation Details

Yangjiang’s Oil distillation machine already installed at domestic, such as Guiyang, Tianjin(20Ton per day), Shandong, Fujian(50Ton per day), Jiangsu(30Ton), Inner Mongolia, Taiwan(30Ton per day), also has exported to different countries, like Russia(0.5Ton per day), Greece(20Ton per day), Algeria(10Ton per day), Liberia(4Ton per day),Sri Lanka(0.5Ton per day), Malaysia, Indonesia, Bangladesh, South Africa, Mexico, Colombia, Chile, Argentina, etc.

Warmly welcome to contact us to know more about our oil distillation plant and visit our factory at any time. Please feel free to let us know if there’s any question in Business. (+86 133 9980 7550 Whatsapp / WeChat 24-H service).