YJ-SR Solvent Extraction Machine

YJ-SR Solvent Extraction Machine

Yangjiang provides all black used oil recycling equipment and technology. This is more than simply used lubrication oil disposal, we do not just purify used oil, instead, we developed an amazing regeneration process which can reclaim all kinds of waste black lubricating oil to clean base oil and diesel fuel. Yangjiang used oil recycling machine can recover waste black motor oil, waste engine oil, used industry oil, hydraulic oil, transformer oil, we commit to protect the environment by recovering and re-refining of used oil into a pure base oil and diesel oil, help users cut maintenance costs greatly, extend equipment life and significantly reduce waste oil disposal problem.

Solvent Refining Machine is a high-efficiency equipment that use new technology to refine oil into white color oil reach API II standard, and decrease sulfur from diesel oil to 50-100ppm.

Description

The YJ-SR series solvent refining machine by YANGJIANG can refine all kinds of recycled base oil, vacuum cut distillate oil, black diesel oil, waste hydraulic oil, waste transformer oil and all kinds of waste mineral oil which don’t contain solid particle to new oil, with watercolor, the color is less than 0.1 compared with the shade guide.

Why we develop solvent extraction machine?

- With the higher and higher requirement on base oil quality of downstream petrochemical enterprises especially the base oil blending factories, with some old-fashioned technology, the recycled base oil quality is hard to meet the requirement of the downstream user. Before the expensive and technologically complex hydrogenation technology is widely used in oil recycling factory, there are many re-refining technologies, such as fuming sulphuric acid refining technology, lewis acid refining technology, this technology is better than the old fashioned technology, but there’s still a big gap from hydrogenation technology, the environmental pollution problem, the acid sludge, waste white clay disposal are big problems.

- With the strict policy of the National environmental protection department, many many unqualified small oil recycling and oil refining factories were closed by the government. So now, the market requires a kind of efficient, low processing cost, environmentally friendly and pollution-free refining process.

So, YANGJIANG invested a lot of money and manpower to develop this type of environmental protection, energy-saving refining equipment YJ-SR series machine.

Technical Parameter of solvent recycling equipment

| Model | Unit | YJ-SR-5 | YJ-SR-10 | YJ-SR-15 | YJ-SR-20 | YJ-SR-30 | YJ-SR-50 | YJ-SR-100 |

| loss | 1-2% | |||||||

| Temperature range | 0-130C | |||||||

| capacity | Ton/DAY | 5 | 10 | 15 | 20 | 30 | 50 | 100 |

| Total power | KW | 24 | 47 | 50 | 65 | 70 | 85 | 165 |

| Noise | dbA | 45 | 65 | 65 | 70 | 70 | 75 | 75 |

| Dimension | MM | 7500 | 10000 | 11000 | 12000 | 13000 | 20000 | 35000 |

| 3500 | 5000 | 5000 | 6000 | 7500 | 9000 | 16000 | ||

| 6000 | 6000 | 6000 | 6000 | 6000 | 6000 | 10000 | ||

| Weight | TON | 7 | 9 | 15 | 18 | 23 | 30 | 47.5 |

| 1*40 | 1*40+1*20 | 2*40 | 2*40HQ | 3*40 | 3*40+1*20 | 5*40 | ||

| Recommended plant area | square meter | 150 | 270 | 350 | 400 | 600 | 1000 | 2000 |

What the difference between our solvent refining machine and other company’s solvent refining?

- What’s important is our solvent can be recovered and reused, again and again, do not like furfural solvent, which needs to always change solvent.

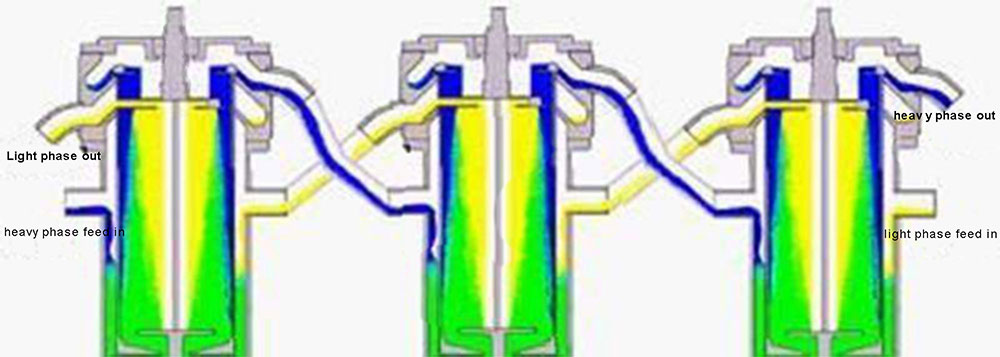

- Other companies use Extraction tower or rotary towers for solvent refining, but We use centrifugal extraction for refining.

- Our solvent is a Self-developed Composite additive, not Single additive.

- The general solvent refining only can get the oil with a color standard of 1.0. Our solvent refining can get the oil with the color standard of 0.1.

Advantages of multifunctional solvent extraction machine:

- The solvent can be recovered, which can be used again and again, the solvent consumption is only 5%-2%.

- Full-automatic: The machine adopts the full-automatic continuously feeding process, no demand for manual labor, one worker can finish all the work.

- Wide range of applications, can refine all kind of mineral oil which don’t contain solid particle to new oil, with watercolor, the color is less than 0.1, all indexes are close to the API II hydrogenated base oil.

- Low loss: Unlike the normal refining technology with high loss, we design a special structure, it can be targeted separately the impurities, sulfides, oxides, colloid, asphalt which has color and may influence the base oil function. Taking the vacuum distilled base oil, for example, the oil loss is about 1-2%; For diesel oil refining, the loss is only 1-1.5%.

- Material: SS#304 stainless steel material

- Refining cost is low: Refining one-ton base oil, the cost is just 200RMB(about 30USD); Refining one-ton diesel oil, the cost is just 150RMB(about 23USD). The cost is much lower than hydrogenation technology and lewis acid refining technology.

- Zero pollution: No waste gas, wastewater and waste sludge. During all the process, we don’t use any oxidizing agent, no chemical, no catalyst, no white clay, no any filtering agent (silica gel, filtering paper, filter cloth).

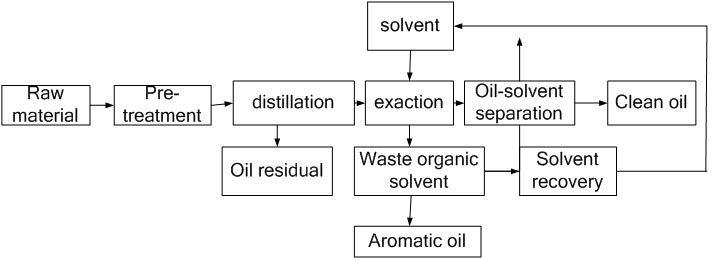

The process of multifunctional solvent extraction machine

How the solvent reacts with the oil?

The solvent and oil are two immiscible solutions, both two immiscible solutions of different densities are pumped into the extractor through two entrances respectively, and then rapidly mixed in the gap between the drum and the shell, and the mixed liquid enters the drum through the inlet at the bottom of the drum, and the accelerated heavy phase is thrown to the lateral side of the drum. the light phase remains on the inside of the heavy phase, the two-phase interface is between the light phase outlet and the heavy phase underflow channel, and the heavy phase underflow channel is in the upper part of the separation zone composed of heavy phase enthalpy.

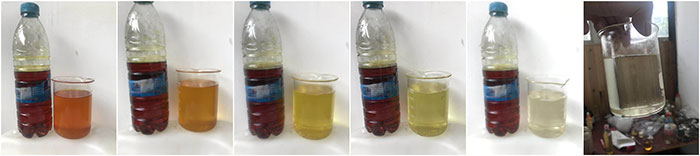

There is a five-stage separator, like the following picture, the oil and solvent were separated two-layer due to the different densities after heating and reacting, the up layer is oil, and the bottom layer is solvent. five times, the oil becomes to water-white color.

Compare with the raw material after reacting with the solvent each time.