YJ-SR Base oil Solvent Desulfurization Machine

YJ-SR Base oil Solvent Desulfurization Machine

YJ-SR Base oil solvent extraction machine can refine all kinds of recycled base oil, vacuum side streams,

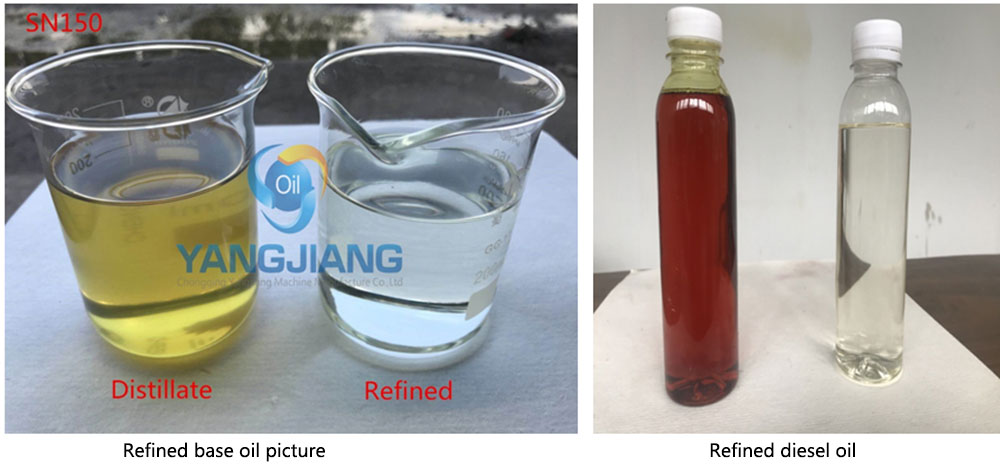

acid-refined oil,black diesel oil, waste hydraulic oil, waste transformer oil and all kinds of waste mineral oil which don’t contain solid particle to new oil, with water color, the color is less than 0.1 . The viscosity, viscosity index, acid value, carbon residue, demulsification value, pour point, saturated hydrocarbon of refined base oil can reach or close to the API II standard, like hydrogenated base oil.

Description

Traditional oil refining processes, such as hydrogenation and acid refining, while effective, often come with significant drawbacks, including high costs, complex technology, and environmental pollution. These methods generate harmful byproducts like acid sludge and waste clay, posing a threat to the environment.

To address these challenges, YANGJIANG Company has developed the YJ-SR Solvent Refining Machine, a cutting-edge solution that offers a more sustainable and cost-effective approach to oil refining. This innovative equipment is designed to refine a wide range of recycled oils, including vacuum side streams, acid-refined oil, black diesel oil, waste hydraulic oil, waste transformer oil, and other mineral oils.

Working Process

- Preheating process: heat the feedstock oil in the pre-heating tank to working temperature, keep stirring.

- First-stage treatment: after preheating, feed the raw material and working solvent to the reactor at the same time, in the reactor, with the special structure, most of the sulfides, oxides, nitrides, colloid, asphalt, arene, unsaturated hydrocarbon can be absorbed by the solvent, then the semi-finished product oil will separate from the solvent and go to the next stage.

- Recycling of working solvent: working solvent will be recycled by the recycling module (distillation kettle), the adsorptive constituents are distilled out and become sludge oil. The working solvent will be vaporized and go into the condenser as the fluid. At last, the recycled solvent will become the new solvent, in the whole processing, the solvent loss is 0.5%-1%, the cost of solvent for recycling 1000Liters oil is less than USD25.

- Thin-film evaporator: the SR machine contains a thin-film evaporator, which function is to separate the tiny solvent from oil, it will keep about 2% solvent after five reactors, so we use the thin film evaporator to separate them.

Output oil picture after solvent extraction machine

Main Part of YJ-SR Base oil Solvent Desulfurization Machine

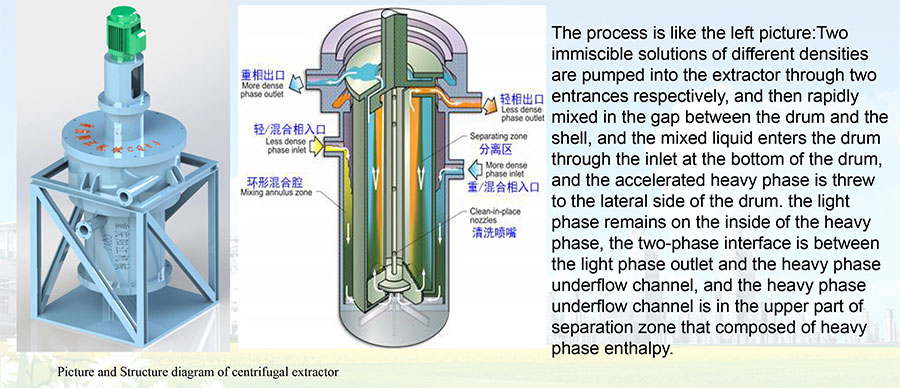

- The main part of SR is the Centrifugal extractor, which can react and separate the oil and solvent quickly.The centrifugal extractor is a new, fast, and efficient liquid-liquid extraction and separation equipment. The YJ-SR series solvent refining machine is aimed at the drawbacks of the traditional centrifugal extractor at present. The centrifugal extractor stage has the advantage of short retention time, rapid phase separation, high extraction efficiency, saving investment costs, and solvent and regeneration costs.

- Two immiscible solutions of different densities are pumped into the extractor through two entrances respectively, and then rapidly mixed in the gap between the drum and the shell, and the mixed liquid enters the drum through the inlet at the bottom of the drum, and the accelerated heavy phase is threw to the lateral side of the drum. the light phase remains on the inside of the heavy phase, the two-phase interface is between the light phase outlet and the heavy phase underflow channel, and the heavy phase underflow channel is in the upper part of the separation zone that is composed of the heavy phase enthalpy.

FAQ

For more information, please contact Kayla, Tel/Whatsapp/wechat:+86 133 9980 7550