YJ-SNC Black Diesel Desulfurization Plant

YJ-SNC Black Diesel Desulfurization Plant

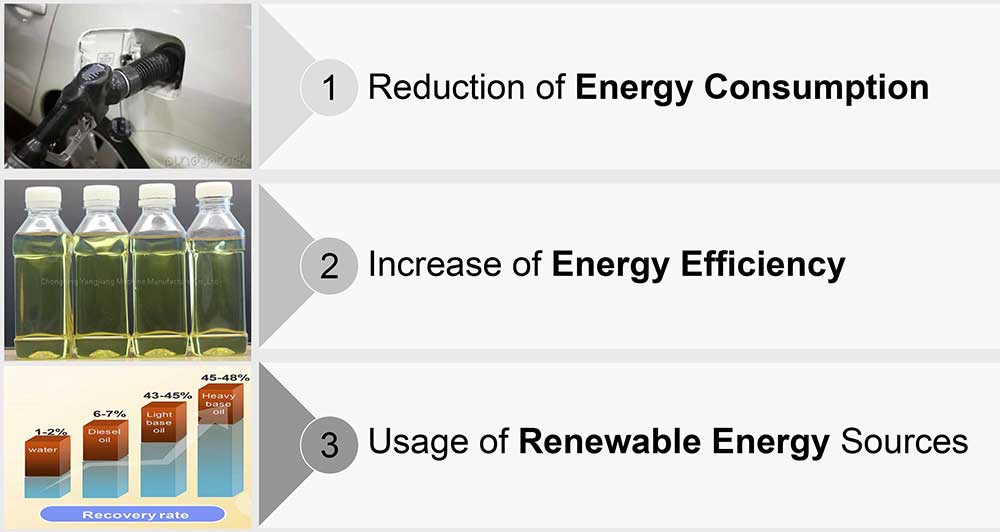

YJ-SNC diesel desulfurization machine can remove sulfur to less than 10ppm, completely remove nitrogen from the oil, and deeply decolorize the oil. The oil contains catalytic cracking distillate diesel fuel, or the diesel from fractionation column, gas oil or pyrolysis oil. The output oil can reach Euro-VI standard that can be reused for vehicles directly.

Features and Advantage:

- PLC or DCS fully-automatic and continuous process

- Around 0.5% Chemical consumption,the chemical additives can be recoverd and reused again and again,and the additive is highly active even in normal pressure and temperature.

- Compared with hydrogenation technology,YANGJIANG’ s desulfurization technology has significant advantages in terms of effectiveness, economy and safety.

- The liquid desulfurization and denitrogenation chemical can quickly dissolve the suspended solids in the oil to obtain a clear and transparent product oil, which can be recycled indefinitely;

- Zero pollution, No oil-bearing waste sludge in the whole process.

- With a 100% recovery rate, the final oil output is essentially split into two parts: light-colored, low-sulfur and low-nitrogen product oil and dark-colored sulfur-rich and nitrogen-rich oil, with negligible oil loss.

- The sulfur can be reduced to less than 10ppm, which can meet the Euro VI standard and can be directly used for vehicles.

Description

YJ-SNC Multifunctional Diesel Desulphurization Plant—Function: desulfurization, denitrification and decolorization, Reduce the sulfur to 10ppm to produce Euro-V standard diesel.

YJ-SNC diesel desulphurization machine can remove sulfur to less than 10ppm, and remove nitrogen from diesel fuel, which contain catalytic cracking distillate diesel fuel, or the diesel from fractionation column,gas oil or pyrolysis oil. the output oil can reach Euro VI standard that can be reused for car directly.

About Yangjiang

Chongqing YANGJIANG has been committed to the research and develop of waste oil recycling and regeneration technoogy since 2005, YAnGJIANG has rich experience, and YANGJIANG’s machines have successfully installed at Shanghai, Tianjin, Inner Mongolia, Shandong, Taiwan, as well as more than 20 countries, such as Greece, South Africa, UAE, Malaysia, Bangladesh, Argentina and so on.

In recent years, environmental protection requirements have become more and more stringent. The sulfur content of diesel oil is required to be less than 50ppm, and some countries require less than 20ppm, or even less than 10ppm. At present, catalytic hydrogenation or hydrocracking is mainly used for reducing the sulfur, but this technology has high requirements for equipment, high temperature and high pressure, high equipment value and large investment. To solve these problems, The YANGJIANG R & D team cooperate with the professors of Wuhan University,research this new desulfurization and denitrification technology,which can reduce the sulfur content from diesel to around 10ppm.

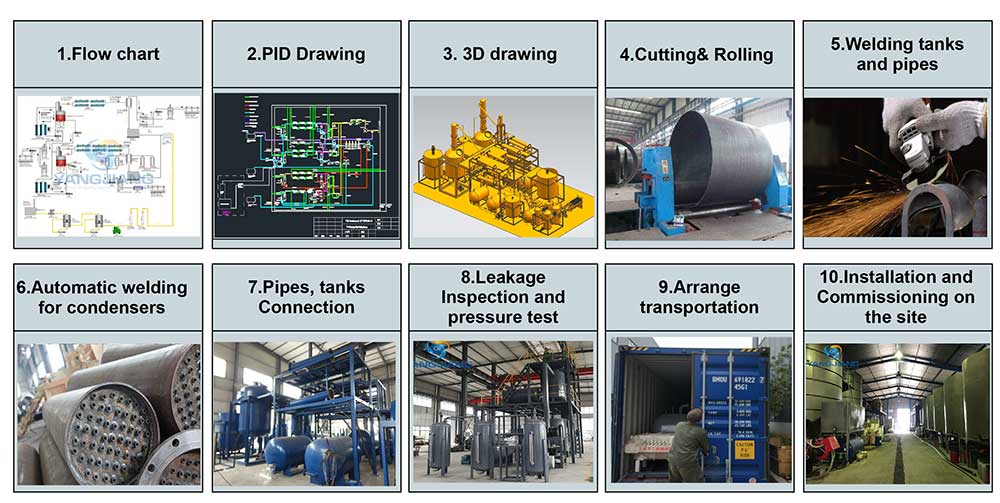

Yangjiang not Only engaged in waste oil equipment manufacturing,but also provides consulting services for the investment and management of waste oil recovery and oil refining projects,Yangjiang has a professional technical team composed of masters and doctors with rich experience in equipment design, providing customers with quality design services in waste oil recovery and oil refining projects,providing customers with engineering design products that meet international standards, national standards and industry standards, including preliminary design, construction drawing design, and software control design. We can provide high quality and advanced design services such as container and pipeline process simulation, 3D design, strength analysis, vibration analysis, safety analysis and software control.

YJ-SNC Plant is specializing in Decolorization, Deodorization,Desulphurization, Denitrification Refining System in One. Which is suitable for refine following oil:

- Diesel fuel from Crude oil

- Diesel oil from waste lube oil

- Black/red diesel

- Pyrolysis oil, like tire oil,plastic oil, rubber oil.

- Heavy oil

Continuously Process Desulfurization Catalyst of diesel Oil Petroleum White Spirit Solvent Technology description

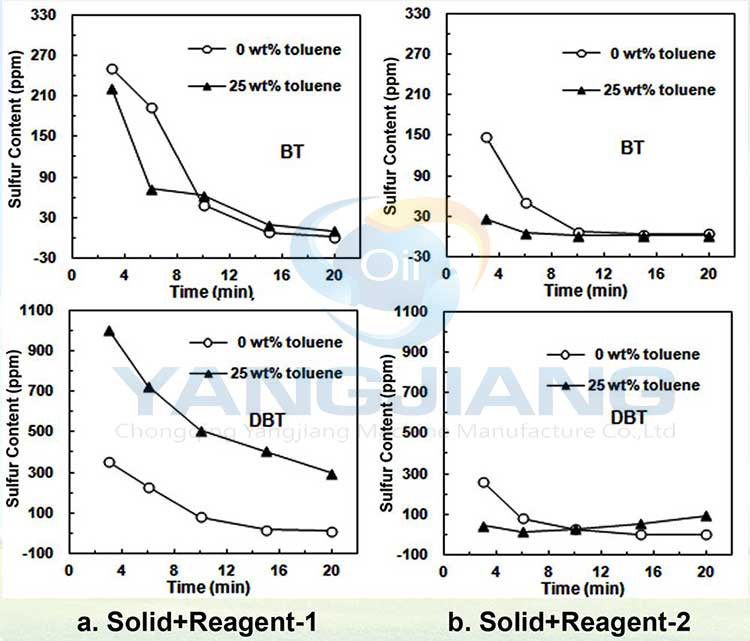

YANGJIANG researched new desulfurization technology, the liquid chemical is used to dissolve the solid positive substances in this technology, so as to realize its liquefaction. Liquefying agents have unique plane structural characteristics, which can disperse the positive charge of the solid positive material in the plane, so as to construct a positive charge structure that can interact with both types of electrons. The method showed excellent effect of removing benzothiophene (BT) and dibenzothiophene (DBT) in oil.

Features and Advantage

- PLC or DCS fully-automatic and Continuous process

- Around 0.5% Chemical consumption,the chemical additives can be recoverd and reused again and again,and the additive is highly active even in normal pressure and temperature.

- Compared with hydrogenation technology,YANGJIANG’s desulfurization technology has significant advantages in terms of effectiveness, economy and safety.

- The liquid desulfurization and denitrification chemical can quickly dissolve the suspended solids in the oil to obtain a clear and transparent product oil, which can be recycled indefinitely;

- Zero pollution,No oily residue in the whole process.

- With a 100% recovery rate, the final oil output is essentially split into two parts: light-colored, low-sulfur and low-nitrogen product oil and dark-colored sulfur-rich and nitrogen-rich oil, with almost no oil loss.

- The sulfur can be reduced to less than 10ppm, which can meet the Euro 6 standard and can be directly used for cars.