YJ-BYL Base Oil Blending Plant

YJ-BYL Base Oil Blending Plant

YJ-BYL Oil Blending Plant can mix oil additives with base oil for producing new hydraulic oil or engine oil(like 10W/40,15W/40,20W/50). It contain additive tank, blending tank, thermal oil heater, condenser, press-filter, and vacuum pump.

1.There is vacuum pump in the machine, it’s better to mix the oil additive with base oil under vacuum for reducing base oil oxidation under vacuum, and its easy to remove tiny moisture.

2.Thermal oil heater: we design to heat the base oil by thermal oil indirectly. First heat the thermal oil, then thermal oil transfer heat to base oil by coil inside the blending tank.Indirect heating will protect the base oil quality.

Working process

- Step 1:Feed base oil, Heat base oil to 40-50degree

- Step 2:Add oil additives evenly in different formula, and open agitator.

- Step 3:The temperature need to control at 65±5 degree

- Step 4:stop heating when temperature up to 60degree,keep mixing more than 2hours

- Step 5:Test the oil, pump the oil into finish product storage tanks when oil parameters match the requirement.

- Step 6: moisture will be separated under vacuum.

The oil additives include viscosity index improver,Dispersants, Anti-wear additive, Oxidation Inhibitors, Pour point depressant, Corrosion Inhibitors etc,we have reliable suppliers of additives who can provide the best quality of additives and blending formula of producing new diesel or gasoline engine oil in API standards,such as SG/CF, SF/CD 15W-40 20W-50,10W-30 etc.

Parameter

| NO | Item | Unit | BYL-2 | BYL-5 |

| 1 | capacity | Ton/Batch | 2 | 5 |

| 2 | handling time | H | 1. 1hour per batch for hydraulic oil 2. 3-4hours per batch,for engine oil | |

| 3 | Temperature range | ℃ | ≤70 | |

| 4 | Working noise | d5(A) | ≤60 | |

| 5 | Power supply | 380V/3P/50Hz or at your option | ||

| 6 | Total power | KW/H | 45 | 75 |

| 7 | Heaitng power | kW | 37 | 65 |

| 8 | Dimension | MM | 2500X1600X2800 | 4000X2200X3600 |

| 9 | Weight | KG | 2000 | 3500 |

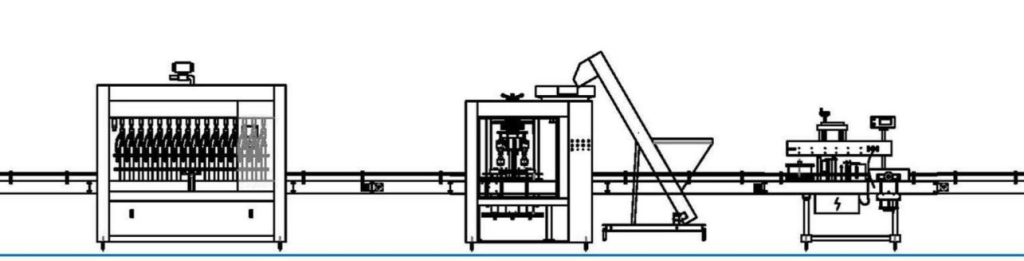

Filling and Packing Lines are optional: