Engine oil, namely engine lubricating oil, is known as the “blood” of automobiles, which can lubricate, clean, cool, seal, and reduce wear of the engine. The amount of oil consumed every year in the world is not huge, so the question is, where does the used oil go? This article will discuss this issue.

What is motor oil?

Engine oil, namely engine lubricating oil, is known as the “blood” of automobiles, which can lubricate, clean, cool, seal, and reduce wear of the engine. The engine is the heart of the car. There are many metal surfaces in the engine that are rubbing against each other. These parts move at high speed and in a poor environment, and the operating temperature can reach 400°C to 600°C. Under such harsh working conditions, only qualified lubricating oil can reduce the wear of engine parts and prolong the service life. Engine oil consists of base oil and additives. Base oil is the main component of lubricating oil, which determines the basic properties of lubricating oil. Additives can make up and improve the deficiencies in the performance of base oil, endow some new properties, and are an important part of lubricating oil.

What is The Role of Oil in an Engine?

- Lubrication: There is rapid relative sliding between the piston and the cylinder, between the main shaft and the bearing bush. To prevent the parts from wearing too quickly, an oil film needs to be established between the two sliding surfaces. The oil film of sufficient thickness separates the surfaces of the parts that are relatively sliding to reduce wear.

- Cooling and cooling: The oil can bring the heat back to the fuel tank and then dissipate it into the air to help the water tank cool the engine

- Cleaning and cleaning: Good engine oil can circulate the carbide, sludge, and worn metal particles on the engine parts back to the oil tank, and through the flow of lubricating oil, the dirt generated on the working surface of the parts can be removed. wash away.

- Sealed and leak-proof: The oil can form a sealing ring between the piston ring and the piston to reduce gas leakage and prevent the entry of external pollutants.

- Anti-rust and anti-corrosion: The surface of the parts can absorb lubricating oil to prevent the parts from contacting with water, air, acidic substances, harmful gases, etc.

- Shock absorption and buffering: After using oil, when the pressure of the engine cylinder port rises sharply, the load of the piston, piston chips, connecting rod, and crankshaft bearing suddenly increases. The load is transmitted and lubricated by the bearing, which acts as a buffer against the shock load it bears.

- Anti-wear: Adding lubricant to the friction surface of the engine can reduce the friction coefficient, thereby reducing frictional resistance, saving energy consumption, and reducing wear: the lubricant between the friction surfaces can reduce abrasive wear, surface fatigue, adhesive wear, etc. cause wear.

How to dispose of waste oil?

In Yangjiang, we refine and reprocess the waste oil through reprocessing. After processing, the waste oil will become a clean energy source that can be used again in a new form.

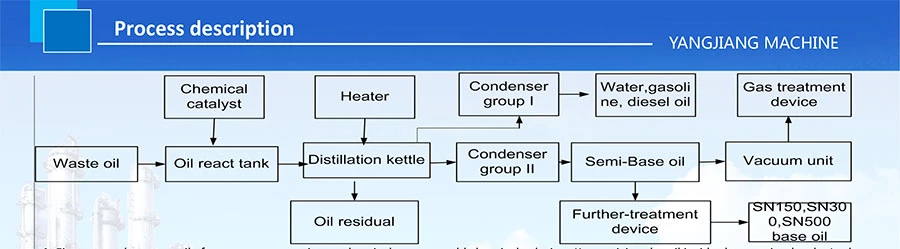

Taking Yangjiang TY-Base oil Distillation-Machine as an example, the treatment method of waste oil is as follows:

- First, pump the waste oil into a chemical reactor, add a chemical solution. Keep mixing the oil inside the reaction kettle. In the reaction kettle make the oil static after mixing, we have the impurities and part of the colloid at the bottom of the reaction kettle separated. After this

chemical catalyst treatment of oil, the oil will not be cracked even it is heated up to 400 degrees in the atmosphere. (in the atmosphere, without the treatment, the oil starts to be cracked at 300 degrees, which declines the quality of recycled oil and recovery rate).

- After chemical treatment, the waste oil is heated by an electric heater, to control the oil temperature within 330 degrees. As the temperature of the waste oil rises to around 55℃, the first cut-off gasoline starts to release from the waste oil. As the temperature of the oil rises to around 110°C – 220°°C, the second cut of diesel oil is released. Base Oil is the main product and its distillation starts at around 220°C and continues up to 330° C. Light base

oil is distilled out around 220°C-300°C, and heavy base oil distills out during 300°C -330°C. Finally, the process ends when the residual material in the waste oil does not vaporize. At this point, the Heating in the distillation process is stopped and the process is essentially complete. We can pump oil residual out to use as bitumen and heavy fuel oil.

- Yangjiang’s machine contained a heating system, the fuel is diesel oil, fuel consumption is about 13-18Liters diesel oil for recycling 1000Liters waste oil.

The treated oil can be reused as clean energy. If you are interested in our Waste Oil To Diesel Refinery Machine or our waste oil recycling technology, you are welcome to contact us. We are Yangjiang, an expert-level waste oil recycling machine supplier.