YJ-DSL Diesel Oil Recycling Plant

YJ-DSL Diesel Oil Recycling Plant

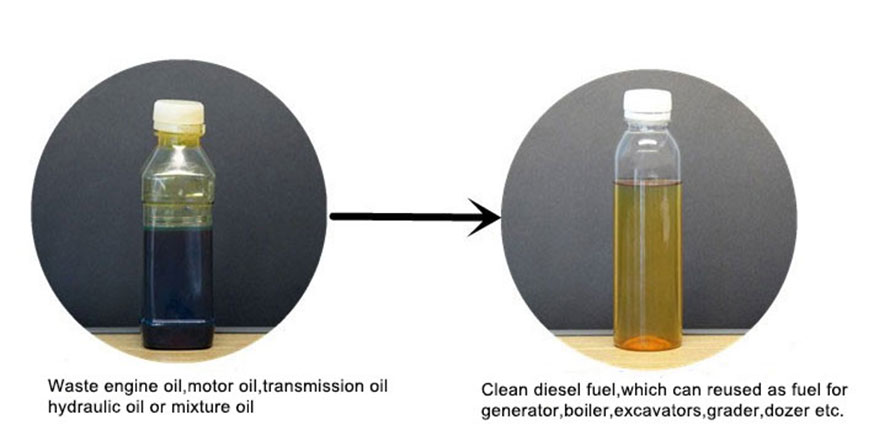

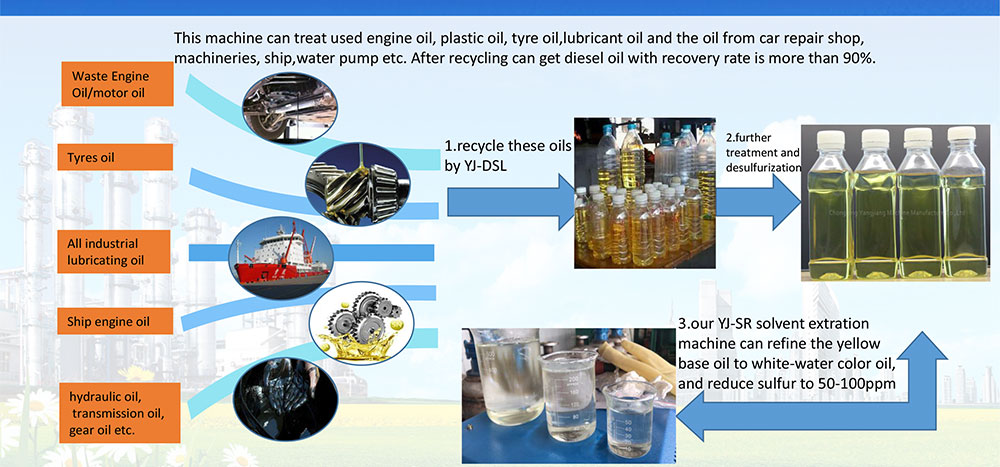

YJ-DSL waste oil to diesel recycling machine can recycle different kinds of waste oil(including waste engine oil, motor oil, ship oil,tire oil, plastic oil, industrial lube oil,hydraulic oil, gear oil etc.)to clean diesel oil,the output diesel oil with flash point 60degree,Cetane index is about 54, and sulfur content is about 300-800ppm, you can add our solvent extraction machine to reduce the sulfur to less than 50ppm.but regarding the plastic oil and tire oil,the sulfur only can be reduced 75%-80%.the output diesel oil can be reused for generator,burner, ship or heavy machines, or construction machines directly.

Description

YJ-DSL series Waste Oil Regeneration Used Oil Waste Car Oil refining To Diesel Recycling Plant can recycle different kinds of waste oil to clean diesel oil,the output diesel oil with flash point 60degree,Cetane index is 54, and sulfur content is about 300-800ppm, you can add our solvent extraction machine to reduce the sulfur to less than 50ppm.

the output diesel oil can be reused for generator,burner, ship or heavy machines, or construction machines directly.

Specification

| Function | Recycle waste oil into diesel |

| What kinds of oil can be recycle | Waste engine oil,motor oil black diesel,Industrial Lube oil,Transmission oil or the mixtural oil |

| Recovery Rate | 85%-90% |

| Heating method | electromagnetic heating system, burner, hot gas or tubular heating system |

| Warranty | 12 months |

Features of the YJ-DSL Diesel Oil Recycling Plant

- Low cost, Recycle one ton used oil need only about 20-25USD.

- Easy to operate, low running cost, it needs only 1-2 workers to operate.

- Can recycle all kinds of used oil. Such as black diesel, used engine oil, used machine oil, used rubber oil, almost all industrial oil and waste plastics oil to diesel fuel.

- The entire process is absolutely environmental protection without any smoke and smell.

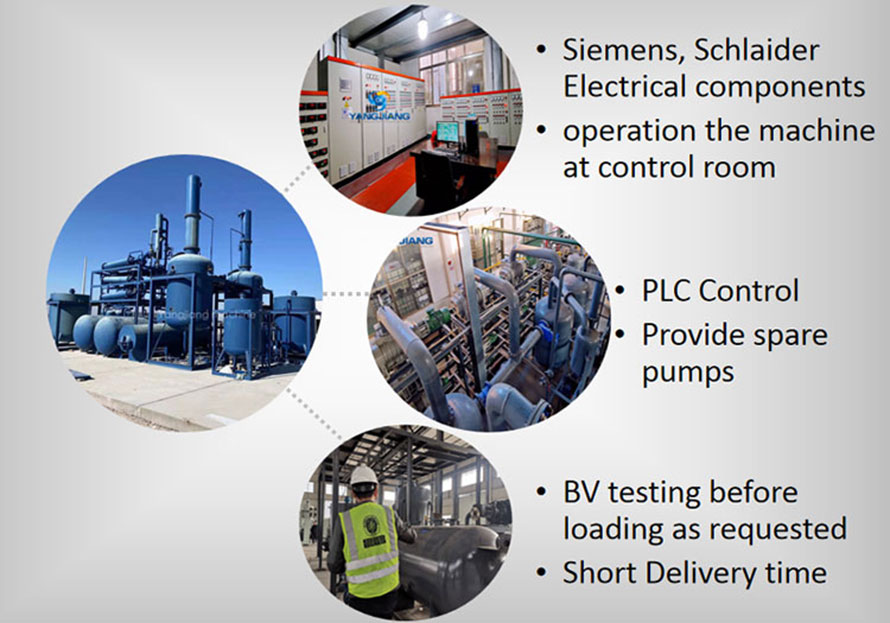

- High-efficiency PLC Electromagnetic heating system, you also can choose gas, burner, etc.

- Exhaust gas from machines will be burned in the distillation chamber, for pre-heating the waste oil.

- High recovery rate: 87%-95%, 3%-5% gasoline, and 85%-90%diesel.

- Desulfuration device for reducing the sulfur to 300-1000ppm, or add our solvent extraction machine to reduce the sulfur to 50-100ppm.

Benefits of YJ-DSL Diesel Oil Recycling Plant

- Used oil is exactly what its name implies: any petroleum-based or synthetic oil that has been used.

- Recycling and reusing used motor oil is preferable to disposal and can provide great environmental benefits.

- Recycled used motor oil can be re-refined into new oil, processed into fuel oils, and used as raw materials for the petroleum industry.

- Our YJ-DSL can process the used engine oil to new diesel, let’s recycle the waste and get profit.

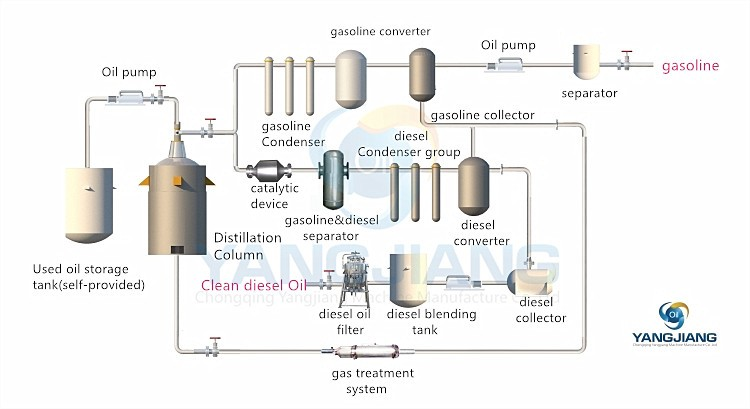

Flow Chart and Working Process

- Start the waste oil pump, Pump the waste oil into the distillation kettle, and then turn on the heating system.

- While heating, start the stirring device inside of distillation kettle. This will help to improve thermal conduction of waste oil, then waste oil can be evenly heated in the distillation kettle. Because waste oil has too much colloid, bitumen, free carbon, heavy metal and other substances, so stirring oil can effectively prevent these substances coking, and blocking distillation apparatus and pipes.

- When the temperature reaches to 50 ℃, gasoline components in the used oil can be gradually distilled out, and be cooled by water and gasoline condenser, then we will get extensive gasoline liquid. When the oil temperature reaches to 100 ℃,water in the used oil begins to be distilled out, water vapor will be cooled by the water and gasoline condenser, then we can collect water liquid,The cooled water and gasoline liquid will enter into the gasoline collecting tank. Because the density of water and gasoline is much different, so they will automatically stratification, then drain water, and filter gasoline,at last we can get the finished gasoline.

- When the temperature reaches to 160 ℃, closed gasoline production line valve, switch to diesel production line.

- With the gradual increase temperature of waste oil, the light components of waste oil will be distilled out and through the efficient catalytic system, which can further catalytic cracking these light components, then gets diesel oil vapor, finally we can get diesel oil liquid after these diesel oil vapor be cooled by diesel oil condenser.

- When the oil temperature reaches to 260 ℃, the heavy components inside used oil will be distilled out and become oil vapor, then go through the efficient catalytic system, which can further catalytic cracking these oil vapor, after cracking these oil vapor will enter a catalytic converter by adding certain amount of additives. Pump these oil vapor back into the efficient catalytic system and let be cracked and catalyzed again.So that we can get higher quality diesel oil vapor, finally we can get the diesel oil liquid after these vapor be cooled by diesel oil condenser.

- Finally, we filter all collected diesel oil liquid, then we can get high quality finished diesel oil

- When temperature reaches about 410℃, start residue oil pump, pump out the oil residue from distillation kettle. The residue oil can be used as heavy fuel oil

Technical Parameter

| 1. Machine Parameter | ||||||||||

| Handling capacity | T/D | 0.5 | 2 | 4 | 5 | 10 | 20 | 30 | 50 | 100 |

| Recovery rate | % | <=93 | ||||||||

| Teperature | ≤ 430 | |||||||||

| Working Noise | dB (A) | 45 | 60 | 65 | 65 | 65 | 70 | 70 | 75 | 75 |

| Total power | KW | 10 | 15 | 20 | 22 | 55 | 90 | 130 | 170 | 260 |

| DimensionMM | L | 5000 | 8000 | 1100 | 12000 | 14000 | 25000 | 30000 | 60000 | 100000 |

| W | 3500 | 4000 | 4500 | 5000 | 8000 | 8000 | 10000 | 16000 | 22000 | |

| H | 6000 | 7000 | 7000 | 7000 | 7000 | 8000 | 8000 | 8000 | 8000 | |

| 2. Output Diesel Parameter: | ||||

| Item | Test standard | Result | Standard value | |

| Density(15℃) | ASTM D1298 | 0.84 kg/l | —- kg/l | |

| Kinematic viscosity(40℃) | ASTM D445 | 3.36 cst | 1.6-5.8 cst | |

| Flash point(closed cup) | ASTM D93 | 60 ℃ | ≥55 ℃ | |

| Pour point | ASTM D97 | -19 ℃ | ≤ 0 ℃ | |

| Distillation temperature | 10% point | ASTM D86 | 204 ℃ | — |

| 50%point | 289 ℃ | ≤300 ℃ | ||

| 90%point | 344 ℃ | ≤355 ℃ | ||

| 95% point | 359 ℃ | ≤365 ℃ | ||

| Cetane index | ASTM D976 | 54.42 | ≥45 | |

| Water content | ASTM D95 | Trace%vol | ≤Trace %vol | |

| Sulfur content | ASTM D1226 | 0.151%wt | ≤0.2 %wt | |

Raw Material Range

By using machines of YJ-DSL type, you can recycle the following types of oil and fuel: including transformer oil; industrial oil; turbine oil; used engine oil; diesel fuel; Crude oil; Heavy fuel; Tire oil and plastic oil or another type of mineral oils.

Material balance (Below table is for your reference, the real condition should be based on your raw material condition):

| Input | |

| Item | Quantity |

| waste engine oil | 1000kg |

| catalyst | 20kg |

| Total input | 1020kg |

| Output | |

| Item | Quantity |

| water | 30kg |

| gasoline | 50kg |

| oil sludge | 80kg |

| diesel | 850kg |

| noncondensable gas(loss) | 10kg |

| Total output | 1020kg |